Polyurethane

Polyurethane is a durable and resilient polymer with several diverse properties and is known for its versatility, meaning it can be used as a soft or rigid foam, a flexible elastomer or a protective coating.

As a material, polyurethane is unique because it can be an elastic like rubber but can be repeatedly stretched and reformed like plastic. This often leaves clients wondering whether rubber or polyurethane is best for their project, but at Aquaseal Rubber, we offer a range of polyurethane plastic products for all bespoke projects.

What is polyurethane?

Polyurethane is found almost everywhere in daily life, from inside the home to in a range of industries, including oil and gas and the offshore and wind energy industry.

Produced by reacting polyols and diisocyanates, polyurethane is a durable but flexible material. There are several polyurethane uses, including:

- Furniture: mattresses, cushions and upholstery foam

- Automotive: car seats and various components, including classic car restoration

- Clothing: spandex and other elastic fibres to ensure a stretchy product

- Construction: rigid foam for insulation in buildings and cold storage

- Footwear: durable but flexible soles for shoes

- Protective coatings: surface protection in the automotive industry or in flooring

Polyurethane hardness is measured using a Shore durometer, a tool which indicates the firmness of polyurethane plastic on a scale which ranges from very soft (Shore A 10-20) to very hard (Shore D 90+). Choosing a shore hardness for polyurethane depends on the desired balance of flexibility, durability and wear resistance for specific applications, but shore hardnesses can be softer than a pencil rubber, harder than nylon or anywhere in between.

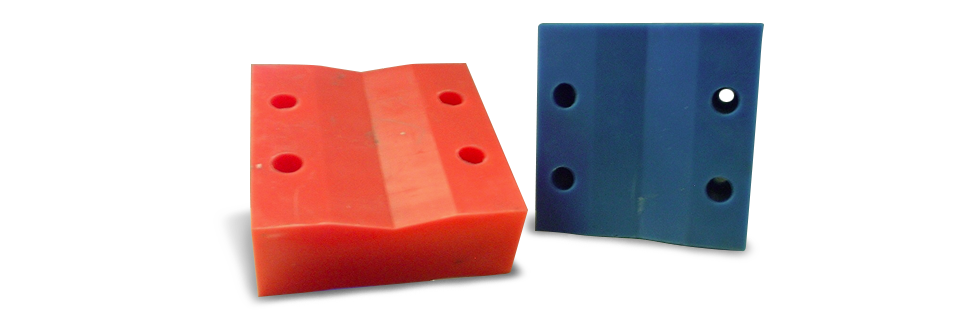

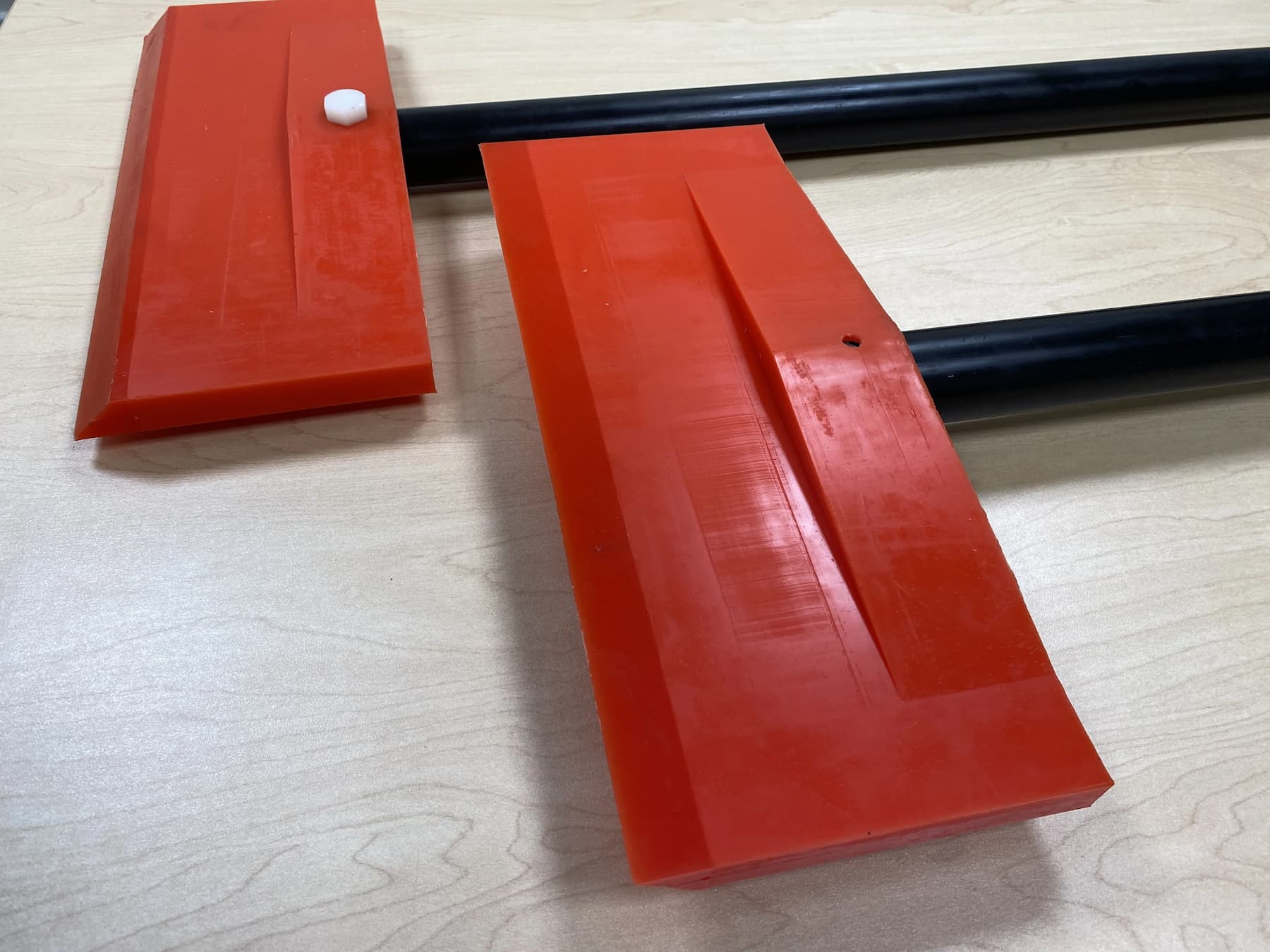

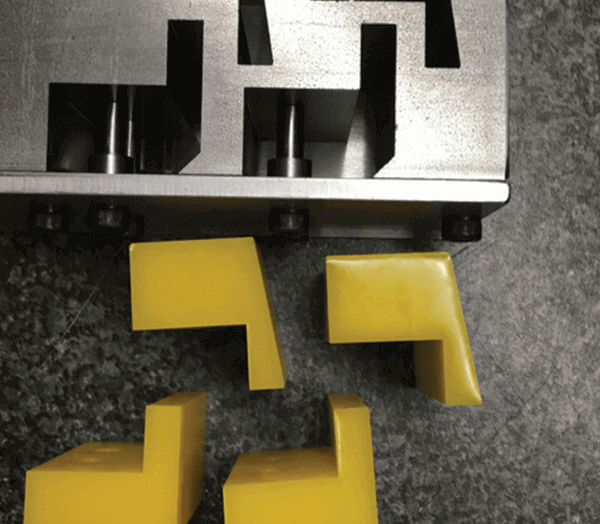

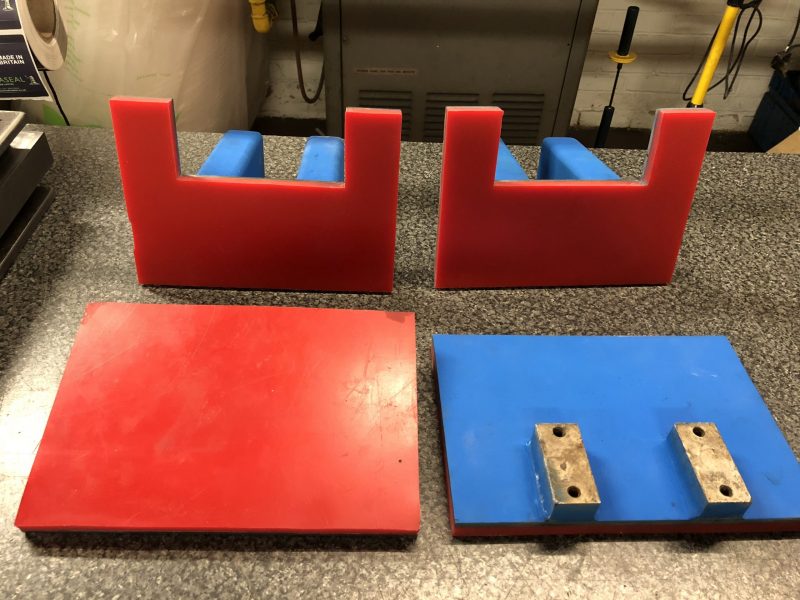

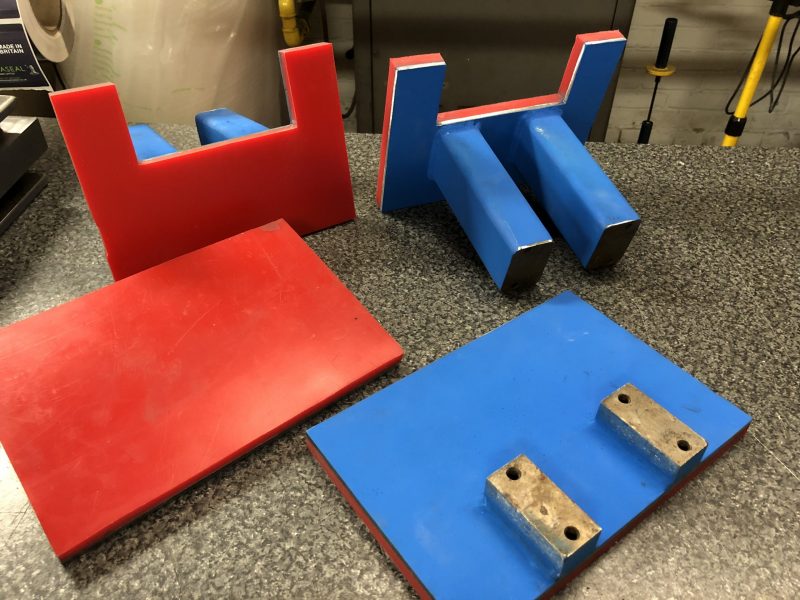

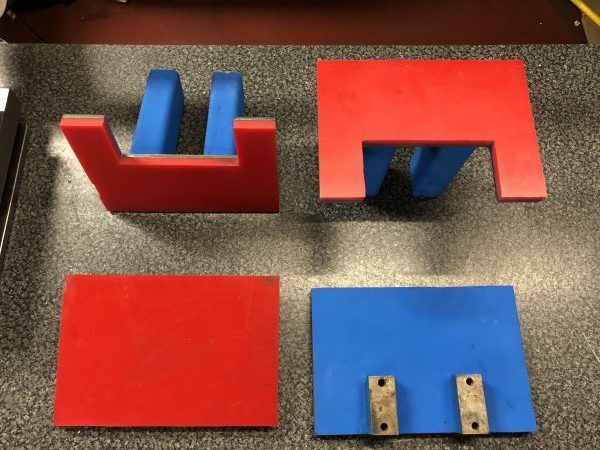

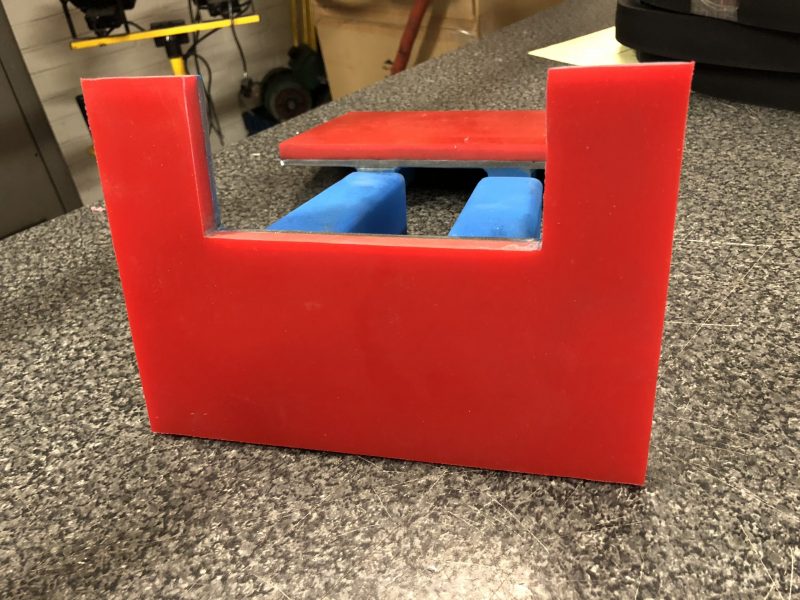

At Aquaseal Rubber, we dispense polyurethane in liquid form into heated moulds from our modern dispensing machines. Then after heat curing, parts are trimmed or machine-finished.

What polyurethane plastic products do we offer?

In the past, our team has manufactured polyurethane plastic for use in a range of applications, from polyurethane clamping plates, polyurethane roller covering and, for a short-notice project, polyurethane mouldings.

At Aquaseal Rubber, we are proud to manufacture and offer a range of polyurethane products to our clients to support their bespoke projects. These include:

- Shocks

- Isolators

- Seals

- Impellers

- Gaskets

- Pinch Rollers

- Capper Rings

- Bushings

- Cams

- Metal Forming Pads

- Cutting Surfaces

- Mounts

- Bumpers

- Bearings

- Blocks

- Elastomers

- Coverings

- Dies

- Gears

- Linings

- Springs

- Straps

- Tubing

- Washers

- Wheels

- Flexible Couplings

- Casters

- Plugs

- Sheets

- Scrapers

- Pads

- Absorbers

Using polyurethane plastic for custom open-cast goods

Open-cast urethane and polyurethane moulding produce a wide variety of products for most industries. Urethane surpasses most other polymers for applications requiring:

- High abrasion resistance

- Outstanding tensile and tear strength

- Noise dampening

- Chemical resistance

- Excellent load-bearing capability

Urethane can replace expensive metal casting because it is lightweight and still maintains or exceeds wear characteristics found in its metal counterparts. We can make polyurethane products to maximise particular specifications, including maximising abrasion and increasing tensile strength.

The ingredients in some urethanes are FDA approved for contact with foodstuffs. This means they can be used as an alternative to food grade rubber in food services and production as well as the medical industry. At Aquaseal Rubber, we can manufacture custom open-cast goods to suit your project requirements through a process which can be used to suit high or low volume production and which produces the most durable urethanes.

Using polyurethane plastic for rubber sheeting

Rubber sheeting can be produced in a variety of dimensions using polyurethane. There are many methods used to create rubber sheeting from polyurethane material, including centrifuged, flat cast, moulded and extruded.

Applications include:

- Cutting or punching gaskets

- Scrapers and flaps

- Protecting industrial tabletops

- Lining wear chutes

- Blast cabinets

The benefits of polyurethane

Polyurethane is one of many different types of synthetic rubber and there are several benefits of using this material as part of your bespoke products.

Used across several industries, including oil and gas and offshore and wind energy, polyurethane is a widely chosen material because of its properties and their related benefits.

Durability and versatility

Since polyurethane plastic is highly resistant to abrasion, chemicals, moisture and weather conditions, it is a long-lasting material which is ideal for use in various products and protective coatings.

Alongside its durability, polyurethane is also extremely versatile. Both strength and flexibility can be combined in polyurethane, and these are qualities that are often difficult to find in other materials like rubber or plastic. Therefore, polyurethane can be formulated for a range of shore hardness.

Moulding capabilities

The moulding capability of polyurethane means that it can be moulded into various shapes with a wide range of hardness. At Aquaseal, we offer a wide shore hardness range from 10°A to 95°D to suit your project. We also offer natural (translucent) or pigmented components in a wide range of colours, including to RAL specification if required. As well as polyurethane’s extensive moulding capabilities, mould costs are also comparatively lower than other rubber or plastic materials.

Environmental resistance

Polyurethane’s environmental resistance means it has numerous benefits, including extended product lifespan and improved energy efficiency. This is because polyurethane is waterproof and has a moisture barrier, as well as being resistant to chemicals, meaning products made from polyurethane are protected from degradation, reducing the need for premature replacement or repairs. Also, as an excellent thermal insulator, polyurethane foam helps to maintain comfortable and stable indoor temperatures, which reduces the need for heating and cooling, ultimately lowering energy consumption.

This makes polyurethane an ideal choice for applications which will be exposed to outdoor conditions and harsh environments.

Adhesion

Choosing polyurethane for adhesive purposes helps to provide optimal longevity of your application. Because of its high bond strength, flexibility that resists vibration and movement and multiple formulation options, polyurethane provides long-lasting bonds for a wide variety of materials, including wood, metals, plastic and concrete.

In many applications, including bespoke projects, the high bond strength of polyurethane adhesives is so effective that it reduces or completely eliminates the need for clamps, screws or other fasteners.

Choosing Aquaseal Rubber for your polyurethane plastic products

With its range of unique properties, polyurethane is a widely preferred material in everyday products, from car wheels and kitchen refrigerators to our clothes, shoes and mattresses. With the ability to be cast into any shape or form, polyurethane has become a widely used material in modern society.

Our essential guide to polyurethane can provide more information about the material and how it may be beneficial for your project.

At Aquaseal Rubber, we manufacture polyurethane plastic products for numerous applications, all of which can be customised to meet the needs of your bespoke project requirements. For more information on how we can support you, or to receive a custom price quotation for your project, contact us to discuss your needs.