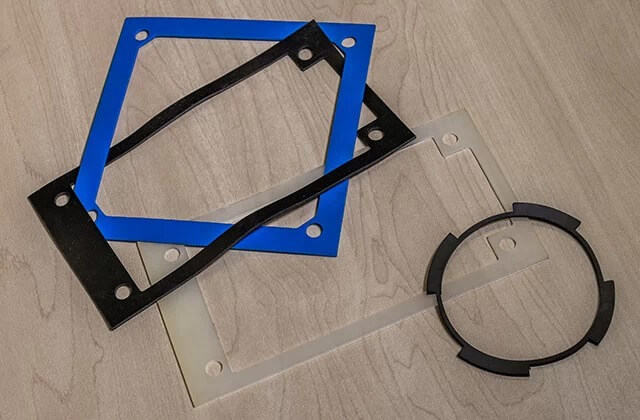

Rubber Gaskets

A rubber gasket is an element that can act as a seal for a range of purposes (this could be for noise reduction, hygiene or liquid sealing). It must be flexible as they are usually compressed between two other surfaces.

Aquaseal Rubber has a comprehensive in-house facility to cut and supply soft-cut, custom hand-cut or die-cut rubber gaskets in any material to suit your needs. We offer press cutting of standard gaskets and also water jet cutting for more demanding requirements.

We manufacture the following gaskets:

- flange

- gas

- water

- automotive

- pump

- food quality

- steam

- marine

- gasket sealants

- spiral wound

In addition to rubber materials, we manufacture our products in the following materials:

- non-asbestos (NCAF)

- treated paper

- cork

- paper-backed cork

- oil tan paper

- Find out more about our materials on our page: “Rubber We Use“

Cutting Rubber Gaskets

Depending on your requirements and desired material, we can use different techniques to create your gasket. Our facilities allow us to manufacture:

- Soft-cut: This type of gasket is flexible and easily compressed between surfaces, they are easy to install and long-lasting.

- Hand-cut: For custom gasket orders, gaskets can be hand-cut with high accuracy using precision tools.

- Die-cut: Dies are metal cutters, shaped to match the desired shape of your gasket. This is an effective process for the efficient production of high quantities.

- Press cut: Using our travelling swing head press and swing beam press, gaskets can be cut of various sizes and thickness.

- Water cut: This process uses a waterjet to cut metal parts with high-pressure water.

Aquaseal Rubber – Materials Chart Gaskets

Use our contact form to enquire further about rubber gaskets or contact us by telephone or email to find out how we could help.